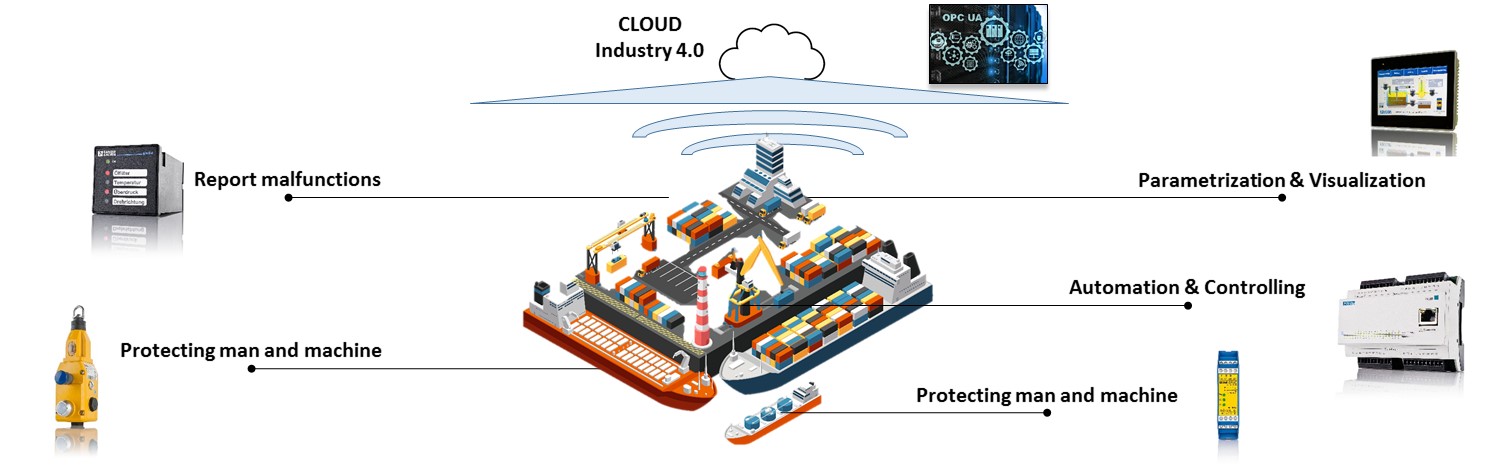

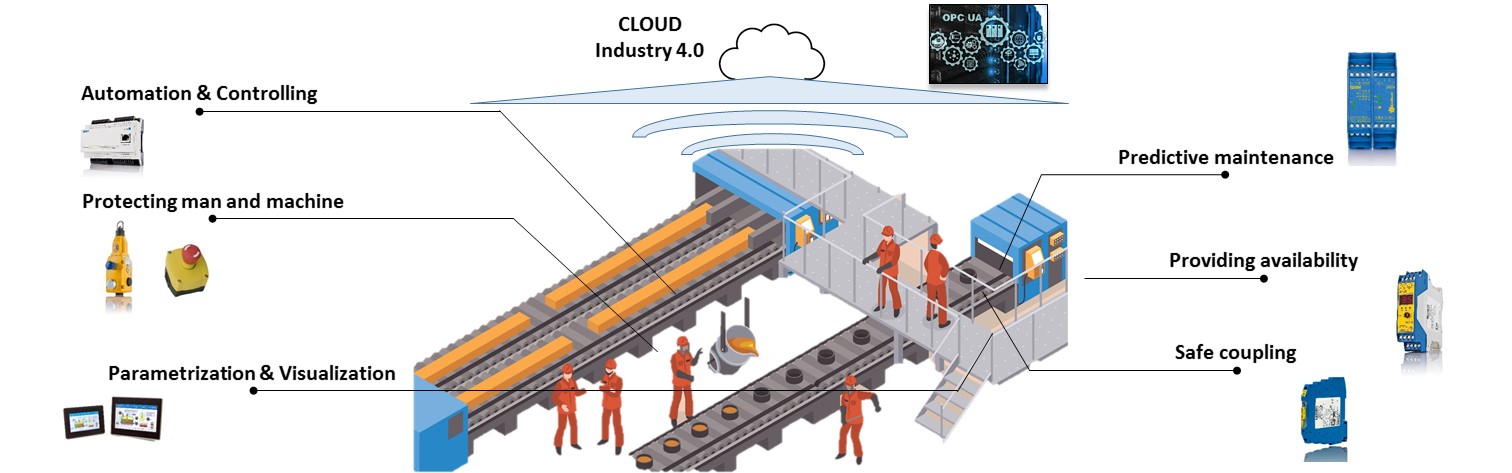

With many years of experience, we offer reliable safety and automation solutions Zander Aachen for nearly every industry.

Including:

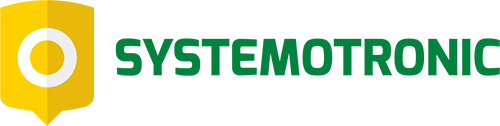

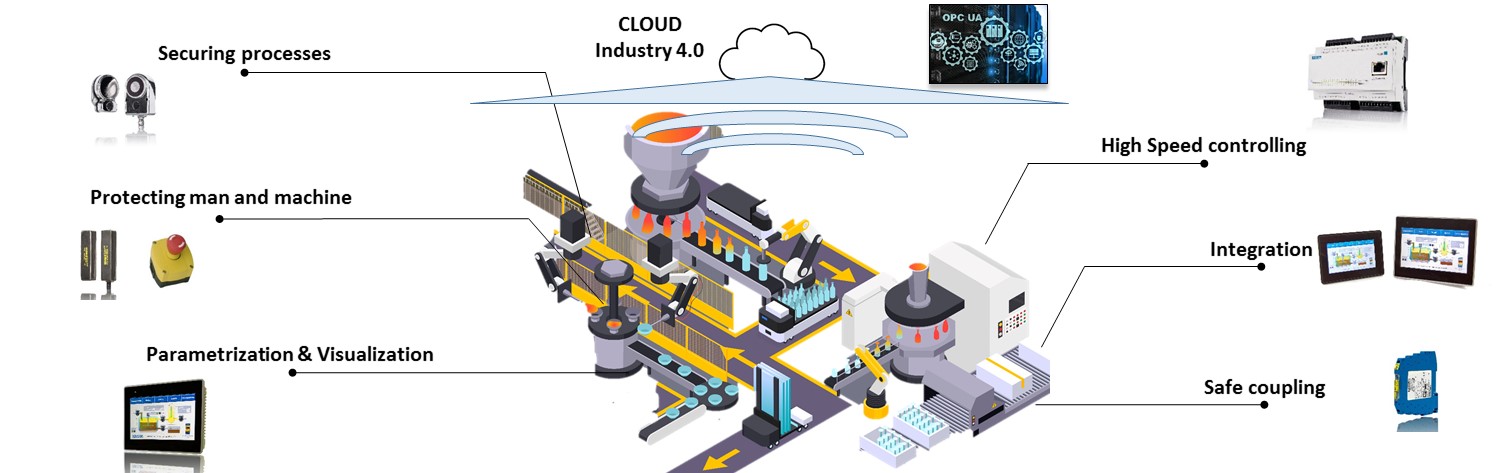

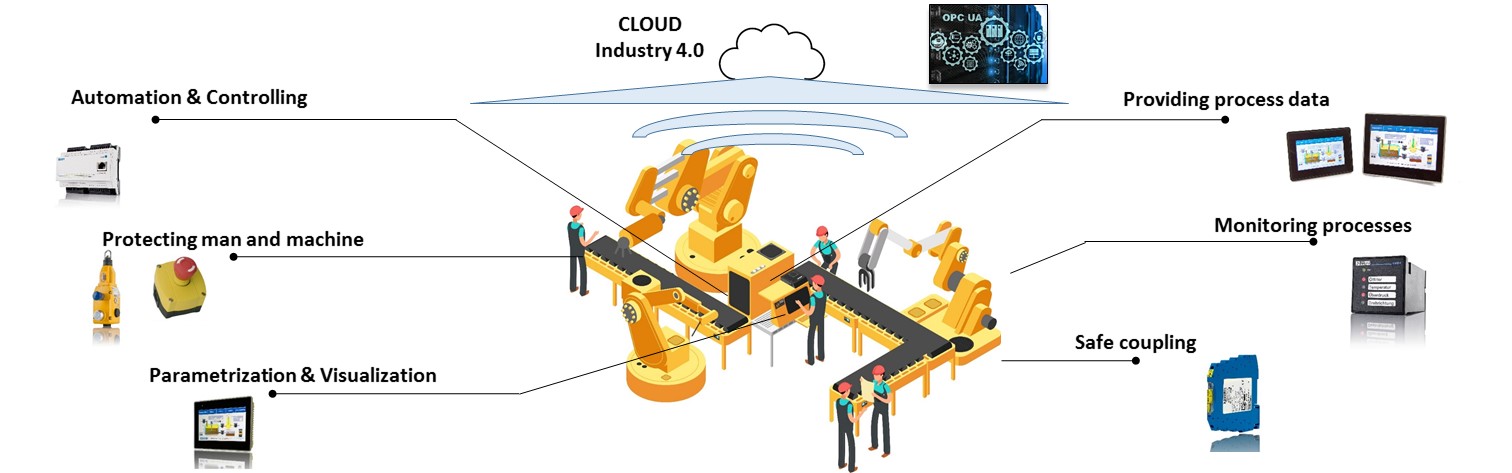

- Automotive Industry

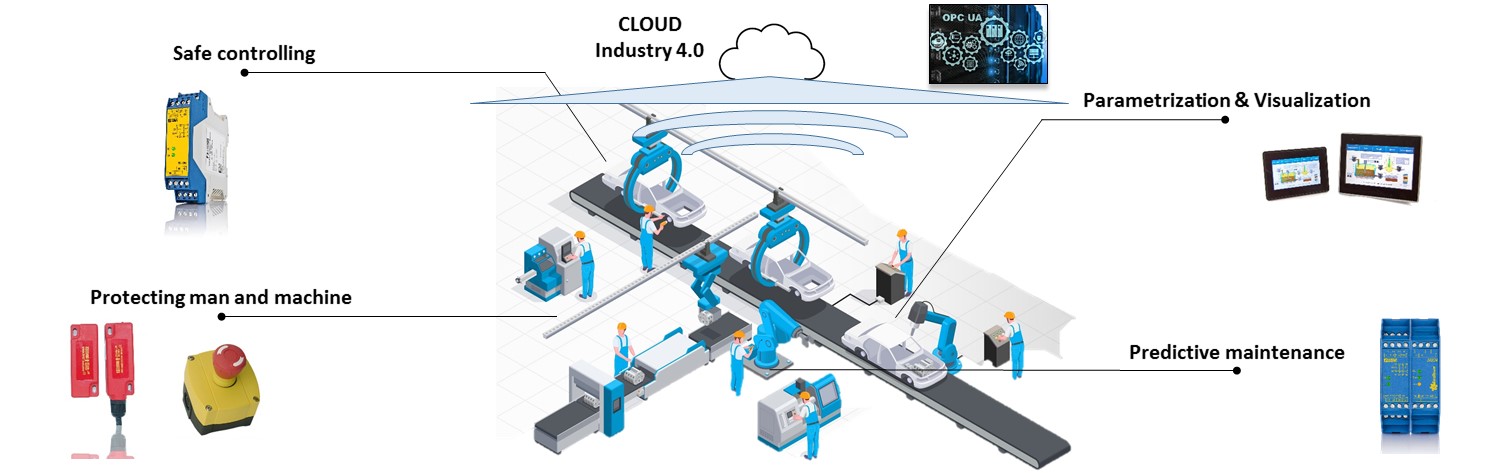

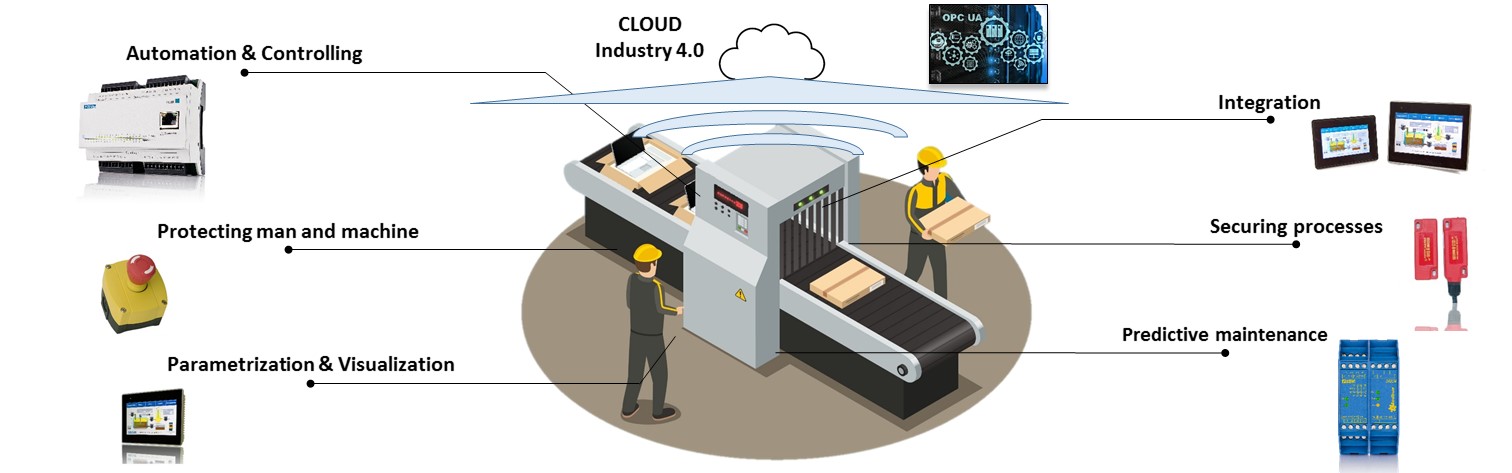

- Conveyor Systems

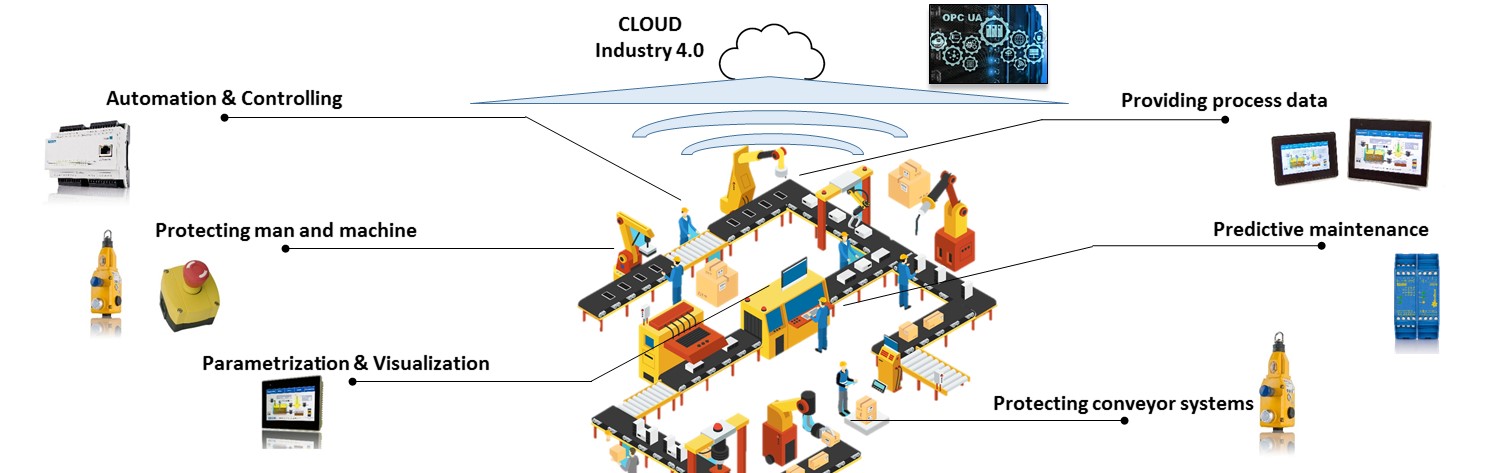

- Elevators

- Food Industry

- Laser Technology

- Manufacturing Industry

- Packaging Industry

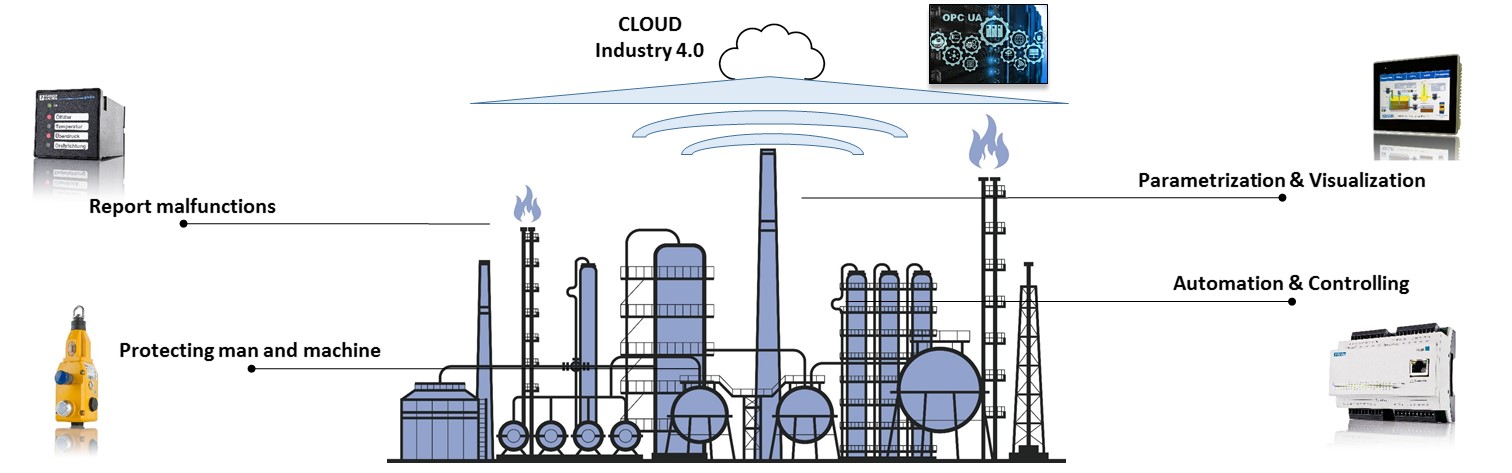

- Process Industry

- Shipping Industry

- Thermoprocesses

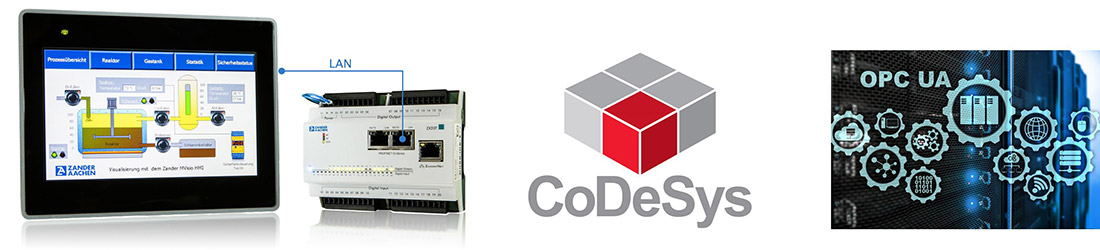

AUTOMATION

High-Speed Industrial controller

The ZX-series provides FPGA controller without cycle-time and jitter with 4 to 20 Inputs:

ZX09 series:

- NEW: ZX09D / ZX09E: 6 high-speed analogue inputs, smaller 5 µs, 0 - 10 V or 4 - 20 mA, additional RS485 / SSI interfaces

- High-Speed connection through ZanderLink, max. 10 µs; up to 18 analogue high-speed inputs, 30 digital inputs

In the field of process intelligence 4.0 we provide different services:

- Software services for High-speed controllers in structured text

- Software services for HMI MVisio in Codesys V3.5

- Software services for the safety controllers TALOS

Our engineering-services ranges from developing customized solutions up to the programming and integration of automation components into requested processes.

DOur know-how and experience with integrating the Codesys integrated development environment as well as our several HMI solutions lead to a variety of opportunities to meet almost every challenge.

What we already can do for you today:

- Remote maintenance and observation via OPC UA

- Fast diagnoses with the support of a digital twin

- Error history with textual description

- Implementation of PID-controllers

- User friendly parameterization with trend indicator

- Password protection with individual access rights

- Language switching

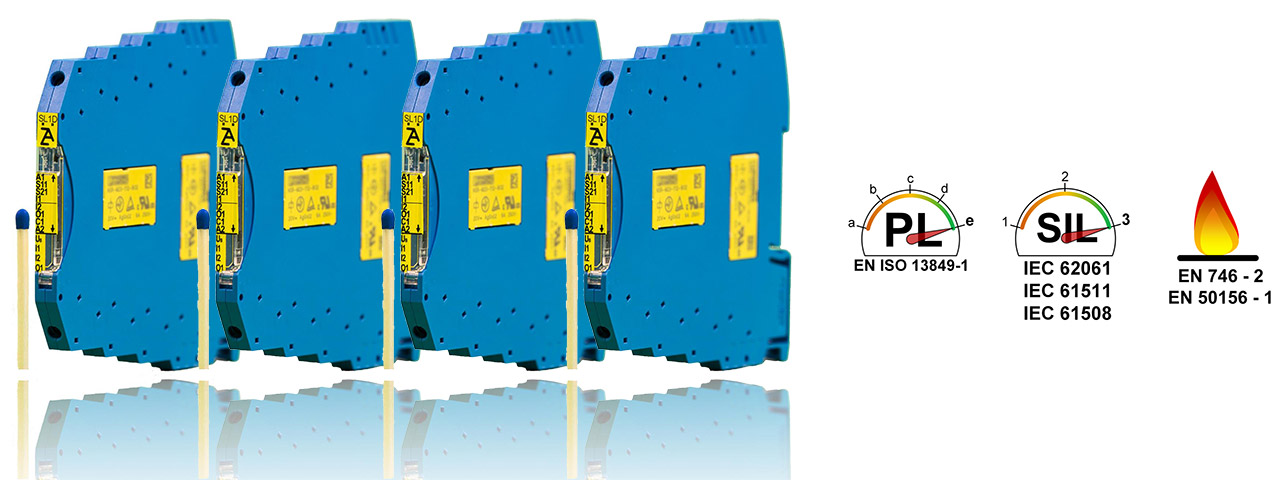

SAFETY

Customized safety solutions for process industries and mechanical engineering:

Safety Timer SCB

- SCB-04: 2 safe relay and 2 safe semiconductor outputs

- SCB-03: 3 safe semiconductor outputs

- SCB-02: 2 safe relay outputs

- And versions up to 99 s, 99 min, 99 h delay time, resolution 0,1, reproducibly and absolute accuracy

Now with new functionalities:

- New switching functionalities of the auxiliary outputs ease the retrofit. With the new variants of the mini safety timer SCB (e.g. SCB-02-01) you have the possibility to integrate the auxiliary outputs, analogue to the classic relay technique, inverted to the control concept. Especially in the case of a retrofit, it ease the exchange of an old, not state of the art pneumatic time relay.

- New functions for an automatic retriggering leads to less system downtime as well as less intervention through the operating personal

- New SCB function for a delayed reset signal to prevent accidental confirmations

Those functions simplify e.g. the retrofit of existing systems, where mechanic and pneumatic timers can easily be replaced by a SCB-variant.

The world’s narrowest safety relay

Those highly compact safety relay‘s with a width from 6 mm pursue one goal:

Providing a modular, minimum-cost safety solution, which is cut to the essentials:

- Wear-free, safe semiconductor outputs (MINOS SL-Series), for e.g. emergency stop button‘s or monitoring safety door’s and light curtains as well as contact strengthening

- Optional relay outputs (MINOS SD-Series), for e.g. high switching loads up to 6A AC 250 V

- Safe coupling relay‘s (MINOS SD1K), for e.g. safe contact strengthening of safe PLC-outputs

Safe Sensors

Our contactless encoded safety switches offer essential benefits in comparison to mechanical safety switches:

- Easy assembly

- High degree of safety against contamination and moisture

- Wear-resistant

- High degree of manipulation safety after ISO 14119 with RFID technology

In addition to that, we provide a variety of versions:

- Versions with plastic housing

- Versions with stainless steel housings, for higher temperatures up to +105°C or requirements for higher chemical resistance towards environmental impacts, pursuant to EHEDG (food conformity)

- Versions with RFID technology

- Versions with magnetic process locking force

- Safety Rope Switches